Building Safer CNG Fueling Stations: Why Quality Nozzles, Receptacles, and Breakaway Couplings Matter

August 25, 2025

What is a 2-Way Ball Valve Used For?

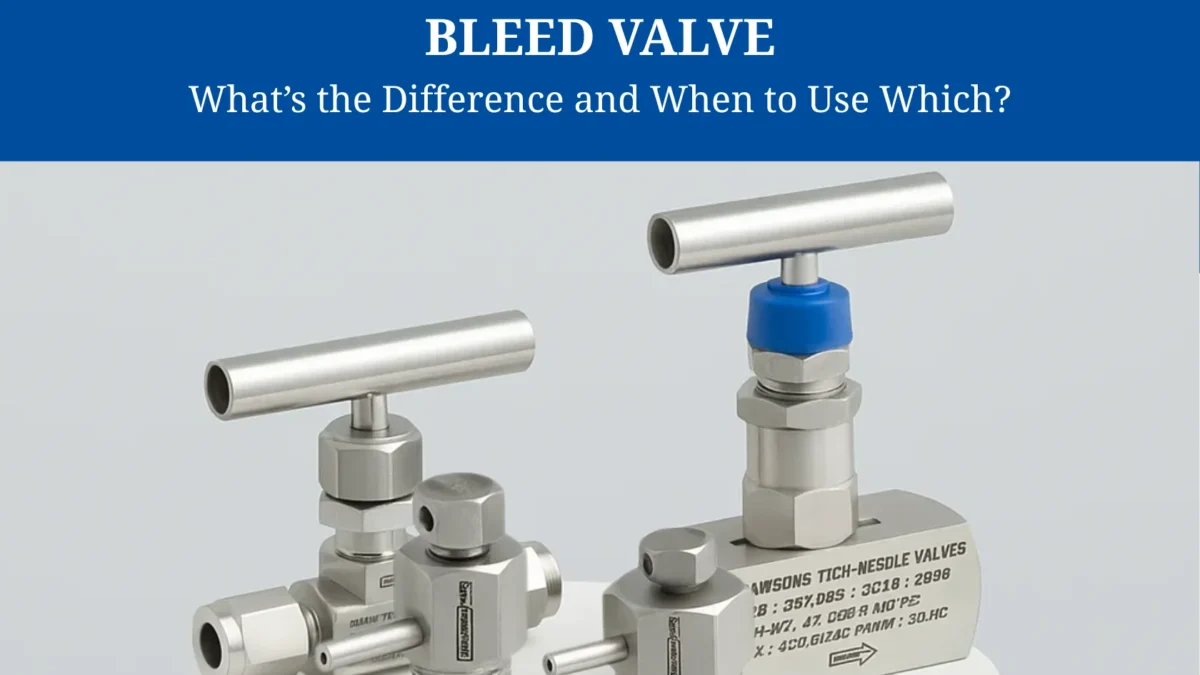

September 25, 2025Needle Valve vs. Bleed Valve: What’s the Difference and When to Use Which?

Introduction

In high-pressure systems—like hydraulic assemblies, instrumentation setups, or CNG fueling infrastructure—the choice of valve types can significantly affect operational safety and precision. At Dawson’s-Tech, our offerings include expert-engineered needle valves and bleed valves—critical components designed for exacting applications.

This comprehensive guide will help you understand the differences between needle valves and bleed valves, when each is most appropriate, and how Dawson’s-Tech ensures uncompromising quality.

- What Is a Needle Valve?

A needle valve uses a fine, tapered stem (needle) that slides into a matching seat to finely regulate flow—ideal for slow, precise adjustments even at low flow rates.

Key Features of Dawson’s-Tech Needle Valves:

- Precise flow control and minimal creep

- Rugged construction using SS316 and PTFE or graphite packing

- Leak-free performance at up to 6,000 psig; the NV109 series rated up to 10,000 psig

- Available in several series, including high-accuracy NV101, precise NV103, and live-load enhanced NV107/ NV107A

- Excellent for instrumentation lines, hydraulic isolation, and pressure gauge mounting.

Ideal Use Cases: Flow regulation in instrumentation, lab equipment, calibration lines, and analytical systems.

- What Is a Bleed Valve?

A bleed valve enables controlled venting—letting trapped pressure or vapors release safely without fully opening the system.

Key Features of Dawson’s-Tech Bleed Valves:

- Vent system pressure safely during operations or maintenance

- Compact and leak-tight—VBL03 series is an example.

- Includes bleeder screw gauge valve series such as NVD31 and NVD41, well-suited for instrumentation and gauge venting.

Ideal Use Cases: Safely purging systems before maintenance, removing air from lines, avoiding sensor damage in calibration.

- Side-by-Side Comparison

| Attribute | Needle Valve | Bleed Valve |

| Primary Function | Fine-tune flow | Controlled venting or purging |

| Typical Pressure Rating | Up to 10,000 psig (NV109) | Similar high-pressure applications |

| Common Series | NV101, NV103, NV107, NV109 | NVD31, NVD41, VBL03 |

| Flow Adjustment | Precise incremental control | Simplified vent function |

| Common Applications | Instrumentation, gauge isolation, fluid control | Vent lines, maintenance safety, purge cycles |

- Hybrid Option: Block-and-Bleed Needle Valves

For applications needing both isolation and venting, block-and-bleed configurations are ideal. These valves allow you to close off flow (block) and safely vent the system downstream (bleed) in a single compact unit.

This dual function is invaluable for maintenance work, calibration routines, and hazardous fluid handling—offering convenience and improved safety.

- When to Use Which Valve

Needle Valve: Opt for needle valves when you need precise control over flow—such as in metering, sampling, or instrumentation circuits.

Bleed Valve: Choose bleed valves when you need to relieve pressure safely—especially before disassembly or measuring pressure accurately.

Block-and-Bleed Valve: Best for systems requiring isolation and venting in tight spaces or where safety protocols demand dual functionality.

- Why Proper Valve Selection is Crucial

Safety

Using the wrong valve can lead to leaks or dangerous overpressure. Needle valves give you precision control; bleed valves help manage pressure safely.

Performance

Needle valves optimize flow accuracy. Bleed valves eliminate pressure traps and prevent damage to sensitive parts.

Durability & Compliance

Dawson’s-Tech valves are constructed to strict tolerances with premium materials (SS316, PTFE/graphite packing) and built to international standards.

- Explore Dawson’s-Tech’s Valve Solutions

Dawson’s-Tech offers a robust catalog of high-performance valves:

- Needle Valve Series: NV101, NV103, NV107, NV107A, NV109—offering choices for precision, live-load stability, and premium pressure control.

- Bleed Valve Series: VBL03 compact venting valve.

- Bleeder Screw Gauge Valve Series: NVD31, NVD41 for controlled venting in instrumentation.

- Additional Options: Gauge/root valves (VGR23) and block-and-bleed manifolds for specialized usage.

- Real-world Application Examples

- Calibration Rigs: Use needle valves (NV103) along with bleeder screws (NVD31) to regulate and vent test benches accurately.

- Hydraulic Systems: Block-and-bleed valves ensure system shutoff while safely removing trapped pressure.

- Gas Manifolds: Needle valves paired with VBL03 bleed valves create safe filling loops with overpressure protection.

Conclusion

Choosing between a needle valve and a bleed valve depends on whether you need accuracy control or safe venting—or both via block-and-bleed configurations. Dawson’s-Tech’s comprehensive valve offerings meet these exacting needs with engineering precision, high-pressure reliability, and compliance assurance.