Understanding Tube Fittings: Types, Applications and Materials

Like a pipe, a tube is a hollow structure created to offer a contained path for fluids to flow. Tubing is typically made from rolled or […]

High Pressure Instrumentation / CNG / Hydrogen Products used in Vehicles, Fueling Equipments

DAWSONS-TECH ® is an ISO 9001:2015 certified manufacturing company offers wide range of Consistent, Reliable and Superior Quality High Pressure Instrumentation / CNG / Hydrogen Products used in Vehicles, Fueling Equipments like CNG Cascades, CNG Dispensers, Booster Compressors, Online Compressors, Decompression Skid, LCV Filling Post, Meter Regulation Skids, Pressure Regulation Skids, etc.

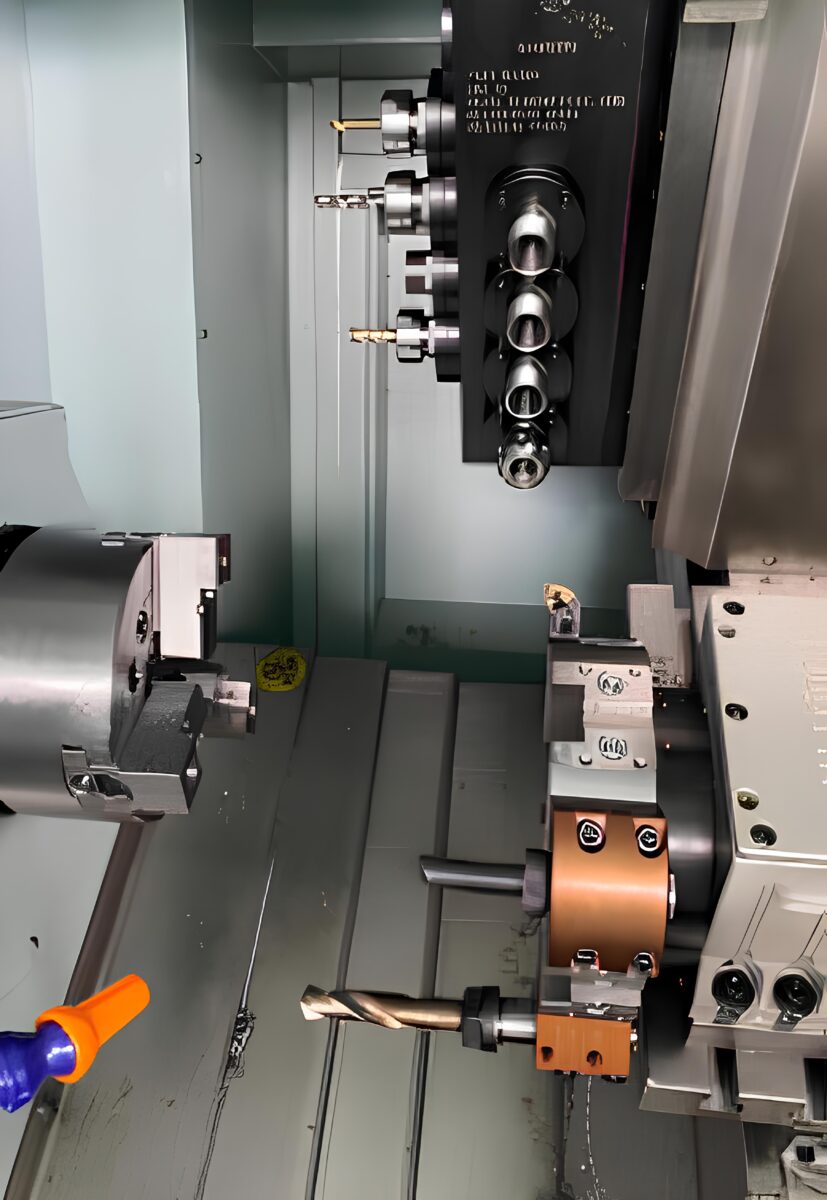

DAWSONS-TECH ® established its comprehensive state of art manufacturing and testing facility installing various CNC Turning Centre and CNC Turnmill Centre, Vertical Machining Centre, etc. with the highly motivated and dedicated team of employees in place. This facilitate us to design and manufacture our product range under stringent quality checks and measurements that ensures “A TOTAL CUSTOMER SATISFACTIONS”.

We strive to achieve total customer satisfaction and continuously work to set higher goals to provide the reliable quality, timely delivery of our products and prompt services in the best interest of our customers with Very Competitive Price.

Based on our exhaustive expertise in product design and its application for excellent product performance exhibiting total safety, integrity & reliability that builds our customers confidence in us

DAWSONS-TECH® persues not only performance of its products but also ensures “TOTAL QUALITY CONTROL MANAGEMENT SYSTEMS IN ACCORDANCE WITH ISO 9001:2015”

With our extensive experience, expertise and continues Research & Development with incorporation of advanced technology DAWSONS-TECH® is committed to constant upgradation

From exploration to production, ensuring excellence at every step.

Products are being manufactured according to applicable technical specifications. Top most objective is to fulfil the requirements of the customer’s

Products are being designed after thoroughly studying the criticality of the applications and to suit the requirements of the customer’s specific needs.

With our Exhaustive Experience, Expertise and Latest Technology, we ensure that every aspect of design, development, production meets to our customers’ expectations.

Like a pipe, a tube is a hollow structure created to offer a contained path for fluids to flow. Tubing is typically made from rolled or […]

Quick connect fittings are a type of connector used to connect fluid lines to equipment. Quick-connect couplings are easy to use without tools and connect with […]

Ball valves are a type of valve that is closed by turning a handle or pulling on a lever. This article will discuss the different types […]

In high-pressure instrumentation systems, even a small connection can determine whether your system performs flawlessly or fails under stress. When it comes to reliable tubing connections in the oil & gas, chemical processing, hydrogen, and power generation industries, twin ferrule tube fittings are widely preferred over single ferrule designs.

In oil & gas plants, chemical processing units, power generation facilities, and CNG systems, pressure instrumentation is constantly monitoring critical operations. But the accuracy of these instruments and the safety of the people working around them depend heavily on how well the system can isolate and release pressure when required.

In oil and gas instrumentation systems, high-pressure valves are safety-critical components, not standard off-the-shelf items. These valves operate in demanding environments where high pressure, temperature variations, corrosive media, and continuous operation are common. A valve that performs well in a general industrial application may fail prematurely in oil & gas service.

High Pressure, Cost Effective & High Performance Components for CNG Vehicles & Fueling Stations.

Feel free to customize it as needed. If you have any specific requirements, please let us know!

Registered Office and Manufacturing Plant:

DAWSONS-TECH COMPONENTS LLP

Unit No. DD – 6 & 7, Khan Real Industrial Estate, N. H. 08, Pelhar, Vasai Phata, Vasai East, Dist. Palghar – 401208, Maharashtra, INDIA.

Email : info@dawsonstech.com

Contact No: +91-9833355596