Quick Connect Couplings Series CQ11 & CQ21: A Complete Guide

October 18, 2025

Threaded Pipe Fittings Guide: Uses, Advantages and Where to Buy

November 22, 2025In every instrumentation system, accuracy and reliability are non-negotiable. Whether you’re isolating a pressure transmitter or performing calibration, the right manifold valve makes a huge difference in both system performance and operator safety.

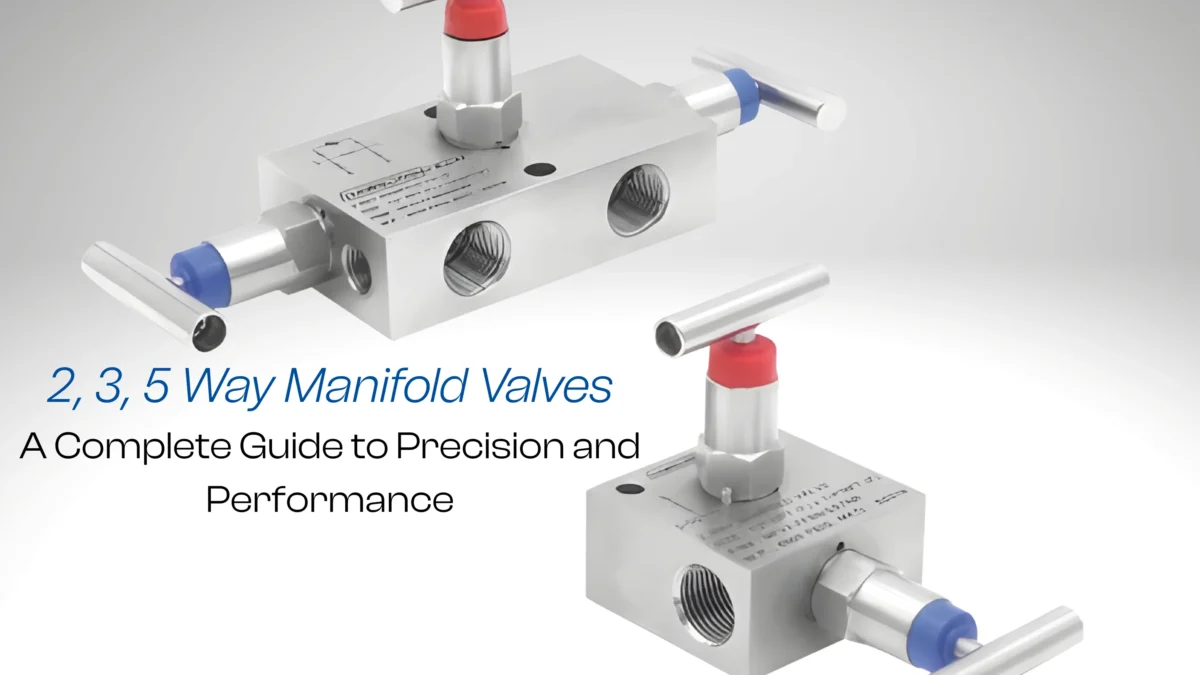

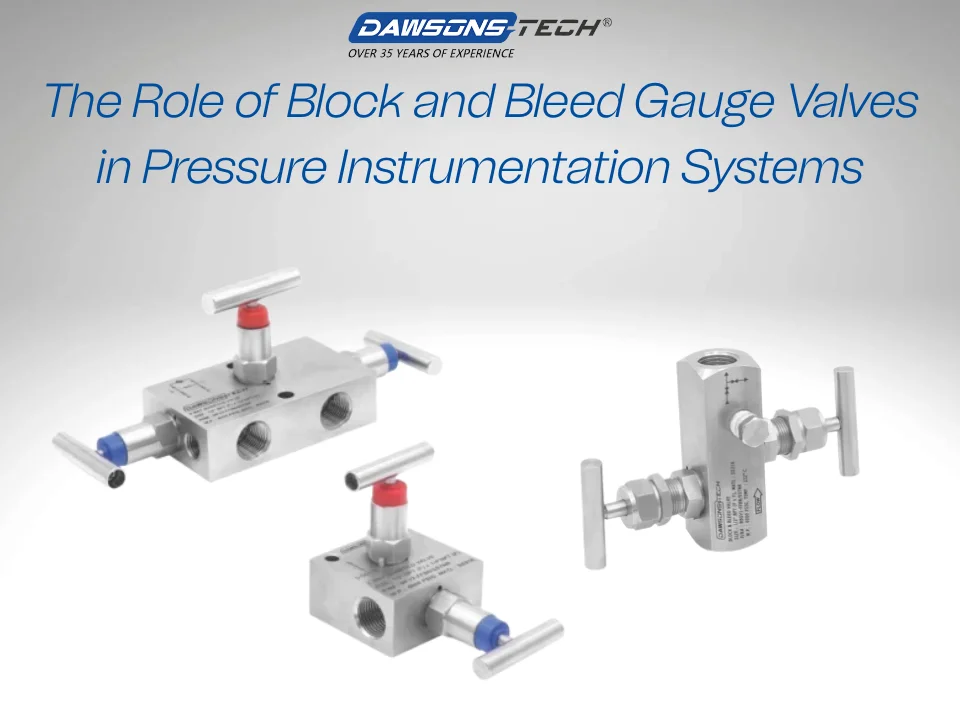

Our 2, 3, 5 way manifold valves at Dawsonstech are expertly designed to reduce leakage, streamline complicated procedures, and guarantee long-term performance in challenging industrial settings.

What Is a Manifold Valve?

A small, multi-valve device known as a manifold valve joins a process line to pressure instruments, including switches, gauges, and transmitters. A manifold blends isolation, equalization, and venting into a single unit rather than several independent valves.

This integration reduces leak paths, saves space, and allows safe calibration or maintenance without interrupting the process.

Product Overview: 2/3/5-Way Manifold Valves

Dawsonstech’s manifold valves are designed for precise pressure control and smooth operation in instrumentation and process applications.

Technical Specifications

Connection Sizes: ½″ BSPP, ½″ BSPT, ½″ NPT (female)

Maximum Working Pressure: Up to 6,000 PSIG (≈ 413 bar)

Body Materials: SS 316 / SS 304 (available in special alloys on request)

Mounting Options: Direct Mount, Remote Mount & Flange Mount Types

Sealing Type: Metal-to-metal seat for leak-free performance

Compliance: NACE MR01-75 for wetted parts

Applications: Pressure transmitters, gauges, and differential instruments

Each valve is manufactured under strict quality standards to ensure zero leakage, long service life, and high pressure tolerance.

Types of Manifold Valves

1. 2-Way Manifold Valve—Compact Isolation and Control

The 2-way manifold valve consists of one block valve and one vent valve. It’s primarily used to isolate pressure instruments such as gauges or transmitters from the main process line.

Applications:

Static pressure measurement

Pressure gauge isolation

Simple process instrumentation

Advantages:

Compact, lightweight design

Easy installation and maintenance

Reliable shut-off and venting

2. 3-Way Manifold Valve—Balanced Pressure and Safe Calibration

The 3-way manifold valve is ideal for differential pressure transmitters. It includes two block valves (for high and low sides) and one equalizing valve to balance the pressures during calibration.

Applications:

Differential pressure measurement

Flow measurement and transmitter calibration

Industrial process control

Advantages:

Safe equalization without process interruption

Protection against transmitter damage

Accurate, repeatable readings

3. 5-Way Manifold Valve-Complete System Control

The 5 way manifold valve is the most versatile configuration. It includes two block valves, one equalizing valve, and two vent valves, providing full control during maintenance and calibration.

Applications:

Continuous process monitoring

Advanced differential pressure systems

High-accuracy flow and pressure transmitters

Advantages:

Complete isolation, equalization, and venting

Safe zero-point calibration without shutdown

Maximum safety and convenience

Comparison Table: 2-Way vs. 3-Way vs. 5-Way Manifold Valves

| Feature | 2-Way Valve | 3 Way Valve | 5 Way Valve |

| Valve Configuration | 1 Block + 1 Vent | 2 Block + 1 Equalizing | 2 Block + 1 Equalizing + 2 Vent |

| Primary Use | Pressure isolation | Differential pressure measurement | Advanced calibration & venting |

| Applications | Gauge isolation | Flow & DP transmitters | Complex process systems |

| Calibration Capability | No | Yes | Yes (Enhanced) |

| Maintenance Flexibility | Simple | Moderate | High |

| Pressure Rating | Up to 6,000 PSIG | Up to 6,000 PSIG | Up to 6,000 PSIG |

| Connection Size | ½″ BSPP/BSPT/NPT | ½″ BSPP/BSPT/NPT | ½″ BSPP/BSPT/NPT |

Why Choose Dawsonstech Manifold Valves?

- Precision Engineering: Each valve is CNC-machined for perfect alignment and leak-proof sealing.

- High Performance: Rated up to 6,000 PSIG, designed for reliability under extreme pressure.

- Material Excellence: Available in SS 316 / SS 304 with NACE compliant wetted parts.

- Compact Design: Saves space and simplifies instrument layout.

- Versatile Mounting: Direct, remote, or flange mounting options suit any setup.

- Tested Quality: 100% pressure-tested for safety and consistency.

Dawsonstech valves are trusted globally in Oil & Gas, Chemical, Power, and Process Industries for their robust build and consistent performance.

FAQs:

- What does a manifold valve do?

It connects pressure instruments to the process line and enables isolation, equalization, and venting, ensuring safe maintenance and calibration without system shutdown.

- Which is better: a 2-way, 3-way, or 5-way manifold valve?

It depends on the application.

- Use a 2-way valve for simple isolation.

- Use a 3-way valve for differential pressure transmitters.

- Use a 5-way valve for complex calibration and venting.

- What is the maximum pressure rating?

All Dawsonstech manifold valves are rated up to 6,000 PSIG (≈ 413 bar), making them ideal for high-pressure instrumentation systems.

Conclusion

Selecting the right manifold valve, whether a 2-way, 3-way, or 5-way, ensures precision, reliability, and operational safety.

When you purchase from Dawsonstech, you’re investing in engineering ability that improves the functionality of your whole instrumentation system, not just a single component.