2, 3, 5 Way Manifold Valves: A Complete Guide to Precision and Performance

October 31, 2025

Why Choose a 3-Way Trunnion Ball Valve? Benefits, Uses & Industry Guide

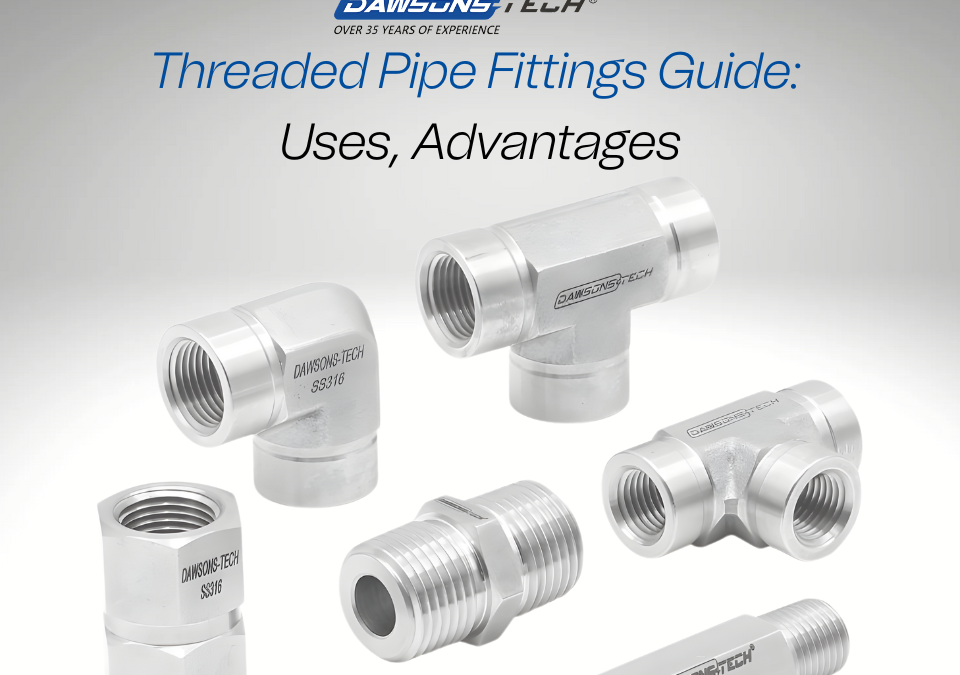

November 29, 2025When you’re designing or maintaining a piping system, the little parts, threaded pipe fittings, make a big difference. They’re the unsung heroes that ensure safety, flexibility, and long-term performance. In this guide, we’ll explore how threaded fittings work, why they remain a favorite in many industries, and why Dawsons‑Tech’s precision thread‑weld fittings are worth your attention.

What Are Threaded Pipe Fittings?

Threaded pipe fittings are components that connect two pipes or a pipe to a device using screw-type threads; no welding is needed. Because they’re not permanent welds, you can assemble, disassemble, or reconfigure your pipeline far more easily. That makes them incredibly useful for systems where maintenance or future changes may be required.

Where and Why These Fittings Are Used

Threaded fittings are used widely across different sectors because of their simplicity and robustness:

- Plumbing & Gas Lines: Perfect for water, air, or gas supply pipelines where reliable sealing is essential.

- Compressed Air and Pneumatic Systems: Great for quick connections and disconnections.

- Industrial & Process Piping: Useful in chemical plants, processing units, or utility pipelines.

- Fire Protection Systems: Commonly used in sprinkler lines because of their dependable threading and sealing.

Because these fittings don’t require welding, you save on installation time and labor costs and avoid the risks that come with hot work.

Key Advantages of Threaded Fittings

- Easy Assembly

No need for welding or flame-based tools. With the right sealant (like PTFE tape or thread compound), a threaded fitting is ready in minutes. - Maintenance-Friendly

If you ever need to modify your setup, inspect, or replace a section, you can simply unscrew and rework without cutting or re-welding. - Cost-Effective

Lower installation cost + lower labor cost = good value. Plus, there’s less downtime for maintenance. - Versatility

Threaded fittings come in many shapes: tees, elbows, adapters, nipples, and a wide variety of thread standards (NPT, BSPP, BSPT, etc.). Dawson‑Tech’s precision thread fittings support many of these. - High Strength & Pressure Capability

Dawsons‑Tech’s threaded-weld fittings are engineered not just for convenience but for durability and strength. Their fittings follow high-pressure ratings, complying with standards like ANSI B31.1.

Types of Precision Thread‑Weld Fittings from Dawsons‑Tech

To highlight how robust and precise these products are, here are some key fittings from Dawsons‑Tech’s lineup:

- Male Tee:

-

-

- Available in NPT sizes from 1/8″ to 1″.

- Strong pressure capabilities, up to 5600 PSIG (380 bar) for certain sizes like 3/8″.

-

- Branch Tee:

-

-

- Combines a female NPT and male NPT branch.

- Pressure rating also goes up to ~5600 PSIG depending on size.

-

- Hex Nipple (Male NPT):

-

-

- Thread sizes from 1/8″ to 1″.

- Very high pressure rating; for 1/8″, it’s 9100 PSIG (620 bar).

-

- Adapter (Female NPT → Male BSP):

-

-

- Converts between different thread types, making your system more flexible.

- Pressure handling is good: e.g., the 1/8″ NPT to 1/8″ BSP version is rated ~6100 PSIG (415 bar).

-

- Male Adapter (BSPT to Tube):

-

- Converts a BSPT threaded connection into a tube end.

- Available in various sizes, including fractional (1/8″, 1/4″, etc.) and metric (6 mm, 8 mm, etc.).

These examples show the engineering strength and versatility of Dawsons‑Tech’s fittings. They’re not generic; they’re precision-made to work at very high pressures and in demanding environments.

How to Choose the Right Threaded Fitting for Your Setup

Here’s a handy checklist you can follow when picking threaded fittings:

- Know Your System Parameters

-

-

- What fluid or gas is flowing?

- What’s the operating pressure and temperature?

- Will the system see vibrations or be static?

-

- Pick the Right Thread Standard

-

-

- Use NPT if that’s your system’s standard. Dawsons‑Tech supports multiple thread types.

-

- Choose Material Carefully

-

-

- Steel or stainless for high strength/corrosion resistance

- Depending on the application, material choice will affect performance and life

-

- Seal Properly

-

-

- Use PTFE tape or a thread sealant to avoid leaks

- Ensure mating threads are clean and undamaged before sealing

-

- Buy from a Trusted Manufacturer

-

- Precision matters: lower‑quality fittings can leak, fail under pressure, or degrade

- Dawsons‑Tech has strong quality control and industry‑grade pressure ratings.

Read More: https://dawsonstech.com/2-3-5-way-manifold-valves-guide/

Where to Buy

If you’re looking for accurate, high-strength threaded pipe fittings or tube adapters, Dawsons-Tech is one of the most reliable manufacturers in the industry.

How to Order:

- Visit Dawsons-Tech’s website and browse the Thread Pipe Fittings & Adapters section

- Use their product catalog to check sizes, pressure ratings, and part numbers

- Contact their team for quotes, support, or technical guidance

Whether you’re running a small setup or a high-pressure industrial line, Dawsons-Tech provides the precision, reliability, and engineering strength your system needs.

Final Thoughts

Threaded pipe fittings may look simple, but when they’re designed with precision, they become a powerhouse of safety, flexibility, and performance. Dawsons-Tech’s thread-weld fittings are built to take on high pressure, harsh environments, and long-term industrial use, without compromising on ease of installation. If you’re planning a new system or upgrading an existing one, choosing the right fittings can make all the difference. And with Dawsons-Tech’s wide range of precision-engineered threaded fittings, you’re in safe hands.