How to Choose the Right High-Pressure Valves for Oil & Gas Applications

January 22, 2026In high-pressure industrial environments, one small valve can make the difference between safe maintenance and serious risk.

In oil & gas plants, chemical processing units, power generation facilities, and CNG systems, pressure instrumentation is constantly monitoring critical operations. But the accuracy of these instruments and the safety of the people working around them depend heavily on how well the system can isolate and release pressure when required.

This is where block and bleed gauge valves play a vital role.

They are not just accessories. They are safety components that protect instruments, technicians, and the overall process.

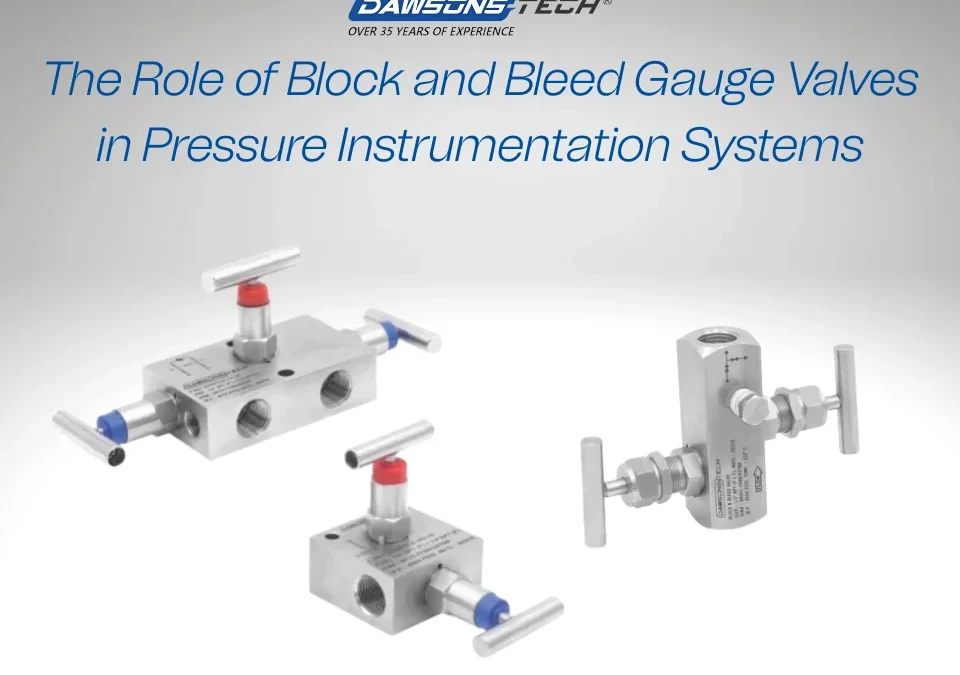

Understanding the Function of Block and Bleed Gauge Valves

A block and bleed gauge valve performs two essential actions:

- Block (Isolation): Stops process media from reaching the pressure instrument.

- Bleed (Venting): Safely releases trapped pressure from the instrument side.

In real industrial conditions, pressure does not simply disappear when flow is stopped. Residual pressure remains in the line. Without a proper bleed mechanism, removing a gauge or transmitter can be extremely dangerous, especially in systems operating at several thousand PSIG.

By combining isolation and venting in one compact design, block and bleed valves make maintenance safer, faster, and more controlled.

Why These Valves Matter in Modern Pressure Instrumentation Systems

1️⃣ Safe Instrument Removal and Calibration

Pressure gauges and transmitters require periodic maintenance and recalibration. Before disconnecting them, the line must be fully isolated and depressurized.

A properly designed block and bleed gauge valve allows technicians to:

- Shut off the process pressure

- Vent trapped media safely

- Confirm zero pressure before service

For EPC contractors and plant operators, this directly reduces operational risk and downtime.

2️⃣ Protects Expensive Instrumentation

Pressure instruments are precision devices. Sudden spikes or uncontrolled pressure exposure can damage internal components.

Block and bleed valves provide controlled isolation, helping to:

- Prevent pressure shock

- Extend instrument lifespan

- Maintain measurement reliability

For international B2B buyers, especially in regulated markets, protecting instrumentation investment is a major concern.

3️⃣ Reduces Leak Points in the System

Every additional fitting or connection increases the chance of leakage. Instead of installing separate isolation and vent valves, a block and bleed configuration integrates the function into a compact assembly.

This results in:

- Fewer threaded joints

- Lower risk of leakage

- Cleaner installation layout

- Improved long-term reliability

In industries where compliance audits and safety inspections are routine, minimizing leak paths is a significant advantage.

Where Block and Bleed Gauge Valves Are Commonly Used

These valves are widely used in:

- Oil & Gas production facilities

- Refineries and petrochemical plants

- Power generation units

- Offshore platforms

- CNG and hydrogen fueling systems

- Industrial process skids

In all these applications, pressure monitoring is continuous and critical. A failure in isolation can lead to operational shutdowns or safety hazards.

Important Design Considerations for B2B Buyers

When selecting block and bleed gauge valves for international projects, buyers should evaluate:

✔ Material Compatibility

Stainless steel such as SS316 or SS316L is commonly preferred due to corrosion resistance and mechanical strength in harsh environments.

✔ Pressure Rating

Industrial systems may operate at high pressures. Always ensure the valve pressure rating matches or exceeds the system requirement.

✔ Connection Standards

International projects require compatibility with NPT, BSPT, or BSPP threads depending on region. Proper selection avoids installation delays.

✔ Compliance & Certification

For European markets, compliance with PED (Pressure Equipment Directive) is essential. ISO-certified manufacturing processes also build trust with global clients.

Block and Bleed vs. Manifold Valves: What’s the Difference?

Many buyers confuse block and bleed valves with manifold valves.

Here’s a simplified distinction:

- Block and bleed gauge valves are typically used for single-pressure instruments.

- 2, 3, or 5 way manifold valves are often used with differential pressure transmitters.

In some configurations, manifold valves can include block and bleed functionality. The correct choice depends on the application design and measurement requirements.

An experienced instrumentation valve manufacturer can guide proper selection based on project specifications.

Why Quality Matters More Than Price

In international B2B projects, procurement teams are not just buying a valve; they are investing in reliability.

A poorly manufactured valve can lead to:

- Instrument damage

- Process downtime

- Safety incidents

- Expensive maintenance

On the other hand, a precision-engineered block and bleed valve improves system safety, simplifies maintenance, and enhances long-term performance.

For global markets, especially in oil & gas and energy sectors, quality consistency and technical support matter just as much as product specifications.

Final Thoughts

Pressure instrumentation systems are only as safe as their weakest component. Block and bleed gauge valves may appear small, but their role in isolation, venting, and maintenance safety is critical.

For industries operating in demanding environments, selecting the right valve ensures:

- Safe maintenance procedures

- Accurate pressure monitoring

- Reduced leakage risks

- Compliance with international standards

In today’s competitive industrial landscape, reliability is not optional; it is expected.

And that reliability often begins with the right instrumentation valve.