Driving Innovation for a Brighter Future

At Dawsons-Tech, we believe in the power of continuous improvement to shape a better tomorrow.

At Dawsons-Tech, we believe in the power of continuous improvement to shape a better tomorrow.

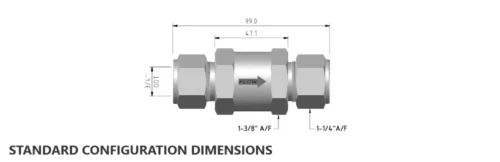

DAWSONS-TECH® Check Valve Series : VC51 is a very compact, robust and heavy duty designed for unidirectional flow control of fluids and gases for high pressure (UPTO 6000 PSIG) used in Instrumentation system.

It is used in various applications where high integrity leak rates and re-sealing capabilities are desired.

The design of DAWSONS-TECH® Check Valve Series : VC31 has been tested for Hydrostatic Proof and Burst Test in accordance with MSS SP-99-2016a Clause 5.5 & 5.6.

The certificate to 3.1 acc. to EN10204 for Valve Body Material and pressure test will be provided on request.

| Sr. No. | Description | Material |

| 1 | Inlet Body | SS316 |

| 2 | ‘O’ Ring | Fluorocarbon |

| 3 | Poppet | SS316 |

| 4 | Spring | Stainless Steel |

| 5 | Outlet Body | SS316 |

| 6 | ‘O’ Ring | Fluorocarbon |

| End Connection | Flow Data | A (mm) | A/F (Inch) | Dawsons-Tech Part No. | ||

| Type | Size | Orifice (mm) | Cv | |||

| Male NPT | 1/4 | 4.7 | 0.75 | 55.0 | 11/16 | VC35-MM4N |

| 3/8 | 7.8 | 2.13 | 60.0 | 1 | VC35-MM6N | |

| 1/2 | 7.8 | 2.13 | 69.2 | 1 | VC35-MM8N | |

| 3/4 | 15.0 | 6.0 | 83.5 | 1-5/8 | VC35-MM12N | |

| 1 | 15.0 | 6.0 | 93.3 | 1-5/8 | VC35-MM16N | |

| Female NPT | 1/4 | 4.7 | 0.75 | 54.1 | 11/16 | VC35-FF4N |

| 3/8 | 7.8 | 2.13 | 64.8 | 1 | VC35-FF6N | |

| 1/2 | 7.8 | 2.13 | 83.6 | 1-1/16 | VC35-FF8N | |

| 3/4 | 15.0 | 6.0 | 90.1 | 1-5/8 | VC35-FF12N | |

| 1 | 15.0 | 6.0 | 97.3 | 1-5/8 | VC35-FF16N | |

| Fractional Tube Fitting | 1/4 | 4.7 | 0.75 | 61.8 | 11/16 | VC35-TT4 |

| 3/8 | 7.8 | 2.13 | 70.0 | 1 | VC35-TT6 | |

| 1/2 | 7.8 | 2.13 | 75.3 | 1 | VC35-TT8 | |

| 3/4 | 15.0 | 6.0 | 89.5 | 1-5/8 | VC35-TT12 | |

| 1 | 15.0 | 6.0 | 98.5 | 1-5/8 | VC35-TT16 | |

| Metric Tube Fitting | 6 mm | 4.7 | 0.75 | 61.8 | 11/16 | VC35-TT6M |

| 8 mm | 6.4 | 2.02 | 68.5 | 1 | VC35-TT8M | |

| 10 mm | 7.8 | 2.13 | 71.1 | 1 | VC35-TT10M | |

| 12 mm | 7.8 | 2.13 | 75.3 | 1 | VC35-TT12M | |

| 22 mm | 15.0 | 6.0 | 88.5 | 1-5/8 | VC35-TT22M | |

| 25 mm | 15.0 | 6.0 | 98.5 | 1-5/8 | VC35-TT25M | |

High Pressure, Cost Effective & High Performance Components for CNG Vehicles & Fueling Stations.

Feel free to customize it as needed. If you have any specific requirements, please let us know!

Registered Office and Manufacturing Plant:

DAWSONS-TECH COMPONENTS LLP

Unit No. DD – 6 & 7, Khan Real Industrial Estate, N. H. 08, Pelhar, Vasai Phata, Vasai East, Dist. Palghar – 401208, Maharashtra, INDIA.

Email : info@dawsonstech.com

Contact No: +91-9833355596