Driving Innovation for a Brighter Future

At Dawsons-Tech, we believe in the power of continuous improvement to shape a better tomorrow.

At Dawsons-Tech, we believe in the power of continuous improvement to shape a better tomorrow.

DAWSONS-TECH® Check Valve Series : VC31 is a very compact and robust in construction and designed for unidirectional flow control of fluids and gases for medium pressure (UPTO 6000 PSIG) used in Instrumentation systems.

The design of DAWSONS-TECH® Check Valve Series : VC31 has been tested for Hydrostatic Proof and Burst Test in accordance with MSS SP-99-2016a Clause 5.5 & 5.6.

The certificate to 3.1 acc. to EN10204 for Valve Body Material and pressure test will be provided on request.

| Sr. No. | Description | Material |

| 1 | Inlet Body | SS316 |

| 2 | ‘O’ Ring | Fluorocarbon |

| 3 | Poppet | SS316 |

| 4 | Spring | Stainless Steel |

| 5 | Outlet Body | SS316 |

| 6 | ‘O’ Ring | Fluorocarbon |

| End Connection | Flow Data | A (mm) | A/F (Inch) | Dawsons-Tech Part No. | ||

| Type | Size | Orifice (mm) | Cv | |||

| Male NPT | 1/4 | 4.7 | 0.75 | 55.4 | 3/4 | VC31-MM4N |

| 3/8 | 9.1 | 2.26 | 75.2 | 1 | VC31-MM6N | |

| 1/2 | 11.5 | 3.53. | 90.4 | 1-1/4 | VC31-MM8N | |

| 3/4 | 15.1 | 6.01 | 103.9 | 1-3/8 | VC31-MM12N | |

| 1 | 16.7 | 6.56 | 114.8 | 1-5/8 | VC31-MM16N | |

| Female NPT | 1/4 | 4.7 | 0.75 | 61.0 | 3/4 | VC31-FF4N |

| 3/8 | 9.1 | 2.26 | 77.0 | 1 | VC31-FF6N | |

| 1/2 | 11.5 | 3.53 | 90.4 | 1-1/4 | VC31-FF8N | |

| 3/4 | 15.1 | 6.01 | 103.9 | 1-3/8 | VC31-FF12N | |

| 1 | 16.7 | 6.56 | 122.9 | 1-5/8 | VC31-FF16N | |

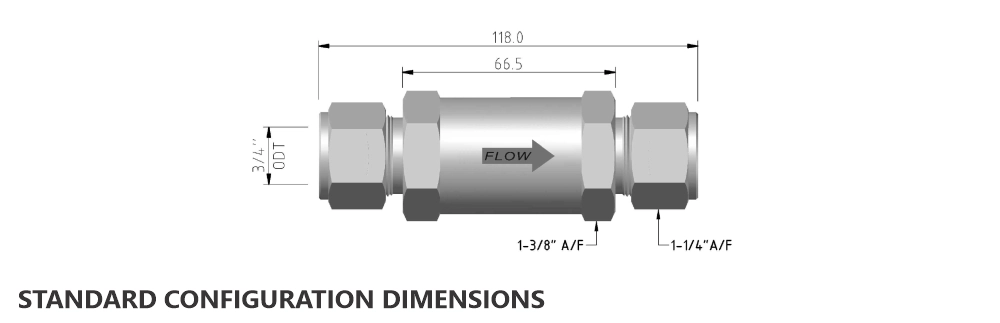

Fractional Tube Fitting | 1/4 | 4.7 | 0.75 | 61.5 | 3/4 | VC31-TT4 |

| 3/8 | 7.1 | 2.09 | 83.1 | 1 | VC31-TT6 | |

| 1/2 | 10.7 | 3.53 | 103.6 | 1-1/4 | VC31-TT8 | |

| 3/4 | 15.1 | 6.01 | 110.2 | 1-3/8 | VC31-TT12 | |

| 1 | 16.7 | 6.56 | 117.6 | 1-5/8 | VC31-TT16 | |

Metric Tube Fitting | 6 mm | 4.7 | 0.75 | 61.7 | 3/4 | VC31-TT6M |

| 8 mm | 6.4 | 2.02 | 84.6 | 1 | VC31-TT8M | |

| 10 mm | 7.9 | 2.16 | 85.1 | 1 | VC31-TT10M | |

| 12 mm | 9.5 | 2.93 | 103.1 | 1-1/4 | VC31-TT12M | |

| 22 mm | 15.1 | 6.01 | 109.2 | 1-3/8 | VC31-TT22M | |

| 25 mm | 16.7 | 6.56 | 120.4 | 1-5/8 | VC31-TT25M | |

Dimensions are for reference only and are subject to change.

High Pressure, Cost Effective & High Performance Components for CNG Vehicles & Fueling Stations.

Feel free to customize it as needed. If you have any specific requirements, please let us know!

Registered Office and Manufacturing Plant:

DAWSONS-TECH COMPONENTS LLP

Unit No. DD – 6 & 7, Khan Real Industrial Estate, N. H. 08, Pelhar, Vasai Phata, Vasai East, Dist. Palghar – 401208, Maharashtra, INDIA.

Email : info@dawsonstech.com

Contact No: +91-9833355596