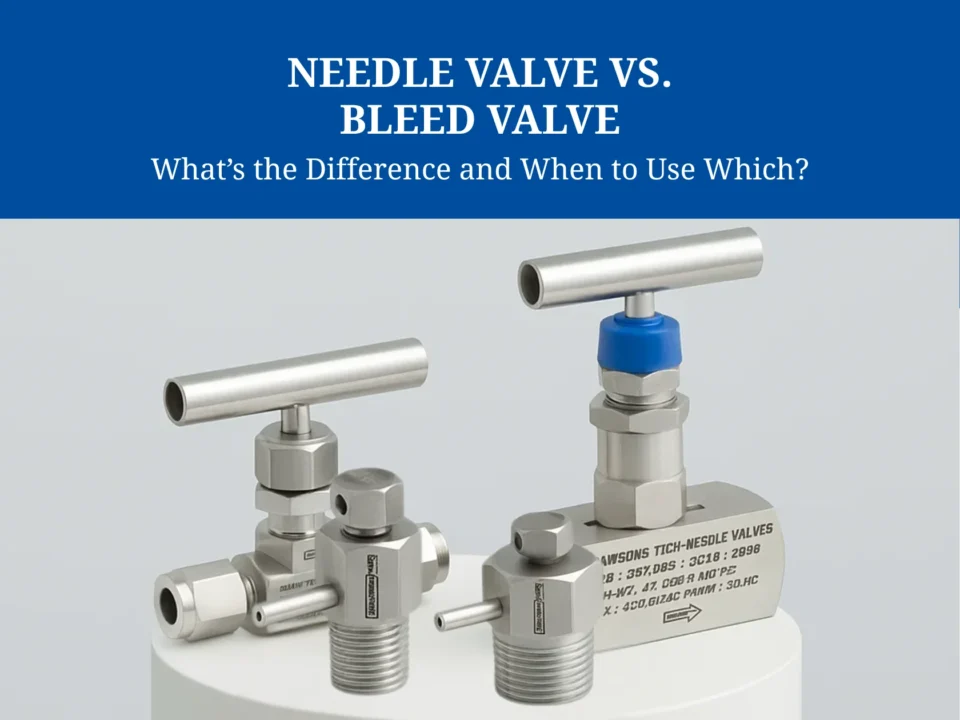

Needle Valve vs. Bleed Valve: What’s the Difference and When to Use Which?

September 15, 2025

Quick Connect Couplings Series CQ11 & CQ21: A Complete Guide

October 18, 2025Table of Content

· What is a 2-Way Ball Valve?

- How Does a 2-Way Ball Valve Work?

- Top Applications of 2-Way Ball Valves

- Benefits of Using 2-Way Ball Valves

- Materials Used in 2-Way Ball Valves

- 2-Way Ball Valve vs 3-Way Ball Valve

- Frequently Asked Questions (FAQ)

- Conclusion

What is a 2-Way Ball Valve?

A 2-way ball valve is a type of shut-off valve designed to control the flow of liquids or gases through a pipeline. It has two ports — an inlet and an outlet — and works in two positions: open or closed.

Inside the valve, a spherical ball with a hole (called a bore) rotates when the handle or actuator is turned. If the hole aligns with the flow path, fluid passes through. If it is rotated 90 degrees, the flow is blocked.

Because of this simple quarter-turn mechanism, 2-way ball valves are popular in industries that require quick shut-off, minimal leakage, and durability.

How Does a 2-Way Ball Valve Work?

The working of a 2-way ball valve is straightforward:

- Open Position – When the handle is parallel to the pipeline, the bore aligns with the ports, and fluid flows freely.

- Closed Position – A 90-degree turn rotates the ball, blocking the flow completely.

This quarter-turn operation makes ball valves faster and easier to use compared to gate or globe valves.

Unlike throttling valves, 2-way ball valves are primarily designed for on/off control, though they can provide some flow regulation in partially open positions.

Top Applications of 2-Way Ball Valves

Because of their versatility, 2-way ball valves are used across multiple industries. Here are the most common applications:

- Oil & Gas Industry

- Used for isolating pipelines during maintenance.

- Provides leak-tight shut-off in high-pressure environments.

- Suitable for crude oil, natural gas, and refinery applications.

- Chemical & Petrochemical Plants

- Handles corrosive liquids like acids, solvents, and other chemicals.

- Stainless steel versions resist corrosion and maintain safety.

- Water Treatment & Distribution

- Used in pipelines for clean water, wastewater, and desalination plants.

- Compact design makes installation easy in limited spaces.

- Food & Beverage Industry

- Sanitary 2-way ball valves made from stainless steel are used in breweries, dairies, and beverage plants.

- Provides hygienic flow control without contamination.

- Power Plants & Industrial Utilities

- Applied in cooling water systems, steam lines, and boiler feed operations.

- Withstands high temperature and pressure conditions.

- HVAC & Plumbing Systems

- Common in heating, ventilation, and plumbing for controlling hot water and chilled water flow.

Benefits of Using 2-Way Ball Valves

There are several reasons why industries prefer 2-way ball valves:

- Quick Operation – A simple quarter-turn opens or closes the valve.

- Leak-Tight Sealing – High-quality seats and seals ensure zero leakage.

- Compact & Lightweight – Easier to install in tight spaces.

- Durable Design – Long service life, even under repeated use.

- Low Maintenance – Minimal wear and tear due to smooth operation.

- Cost-Effective – Affordable solution for both small and large-scale applications.

Materials Used in 2-Way Ball Valves

The choice of material depends on the application:

- Stainless Steel (SS316/SS304) – Best for corrosive environments and high-pressure applications.

- Brass – Cost-effective option for domestic water supply and low-pressure systems.

- PVC / Plastic – Lightweight and chemical resistant, used in irrigation and light chemical handling.

- Carbon Steel – Suitable for industrial applications with high strength requirements.

At Dawsons-Tech, our SS316/316L ball valves are designed for maximum performance, corrosion resistance, and durability across critical industries.

2-Way Ball Valve vs 3-Way Ball Valve

- 2-Way Ball Valve: Has two ports (inlet & outlet) and is used for straight flow on/off control.

- 3-Way Ball Valve: Has three ports and is used for diverting or mixing flow.

If you need simple shut-off control, a 2-way ball valve is the right choice. For flow diversion, consider a 3-way ball valve.

Frequently Asked Questions (FAQ)

Q1. What is the main use of a 2-way ball valve?

A 2-way ball valve is mainly used for on/off control of liquid or gas flow in a pipeline.

Q2. Can a 2-way ball valve regulate flow?

It can partially regulate flow, but it is not designed for precision control. For accurate regulation, needle valves are recommended.

Q3. Are stainless steel 2-way ball valves better than brass?

Yes, stainless steel (SS316/SS304) valves are more durable, corrosion-resistant, and suitable for high-pressure and high-temperature applications compared to brass.

Q4. Where are 2-way ball valves installed?

They are installed in oil & gas pipelines, chemical plants, water treatment plants, HVAC systems, and industrial utilities.

Q5. How long does a 2-way ball valve last?

With proper installation and maintenance, high-quality stainless steel 2-way ball valves can last for many years without leakage.

Conclusion

A 2-way ball valve is one of the most reliable, cost-effective, and widely used flow control devices across industries. Whether it’s oil & gas, chemical processing, water treatment, or food & beverage, these valves provide quick shut-off, zero leakage, and long-term durability.

If you are looking for ISO 9001:2015 certified, high-quality 2-way stainless steel ball valves, Dawsons-Tech Components LLP offers a complete range designed for global industries.